Introduction

My washing machine gave me a hard time only starting after some door opening and closing. Sometimes it would start right away, sometimes I had to try 8 - 10 times until it started washing. I figured that there was a problem with the door switch, witch determines weather the door is closed correctly. I supposed a contact problem, so the maschine thougth the door was still open and hence did not start washing. I did not find any repair device on the Internet, put some people wondering which contact does what. So i took a picture while repairing and tried to figure out what the contacts are for.

Note: Another trouble with the interlock (experienced in another device, but similar symptoms) was caused by displacement of the axis which the lock catch swings on. The round front door was disassembled (screws and plastic latches), the axis was put in its place and fastened with glue.

Tools

-

-

Remove the door interlock from your device. On my washing machine I had to remove the rubber-lid and loosen two screws. Than the interlock came of with a 3-pol cable attached. On the backside was a plastic plate which had to be unscrewed, too.

-

-

-

Pull of the plug and remove the red cover arround the contacts. It is held with two snap-in connectors and its pretty tight (dont destroy the contact cover). Use a small flathead screwdriver to push the hooks away.

-

Remove the top of the red housing. There are six snap-ins to open. Make shure you have removed the contact cover first! Again this is best done with a small flathead screwdriver or blade.

-

-

-

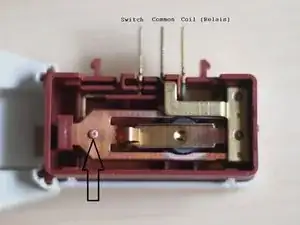

The center contact is common for the switch an the relais. The right one goes to the coil and is for the relais-function of the interlock.

-

The left one is from the door switch. This is what malfunctioned on my washing machine.

-

-

-

The arrow points the contact of the switch. My machine stopped working because the door switch did not work properly. The machine never detected a closed door and hence never started wasching.

-

When the switch closes the copper plate with the arrow in the picture moves down. Underneath ends the switchcontact from outside. It can be removed from the plastic housing. You should gently bend up the copper plate with the arrow. Once removed you can clean the contact area of the bottom switch contact.

-

In my case nailpolish remover did not work, so I scratched the dirt off with a blade. I dont see a way to clean the top contact of the switch, because the copperplate is not removeble. For my switch cleaning the bottom contact was sufficient to get the washing machine working!

-

To reassemble your device, follow these instructions in reverse order.

29 comments

have problems to build the metal flex 446 back together

toy -

Thank you very much for your guidance here.

It has made things so much easier for me in my travails with our misbehaving washing machine and its faulty door-switch!

Thank you a lot Ludwig, it worked perfectly with my ill machine as well! You offered us a great guide. Cheers!

totor -