Introduction

Use this guide to replace the electric motor in your Milwaukee Hackzall 2625-20.

The electric motor in this tool is what rotates the gearbox assembly in your Hackzall, which makes the blade on the end of your Hackzall reciprocate back and forth. A worn-out or failed electric motor can be indicated if: A) the tool is operating at a hotter temperature and performing worse than in previous uses, B) the blade on the end of the Hackzall can be moved by hand but not when the trigger is engaged and a battery is connected to the tool, or C) the Hackzall produces smoke whenever the trigger is pulled and the tool is working properly.

Reasons for the electric motor failing can vary from the elements the tool was exposed to (submerged, burned, buried, etc.), to the amount of maintenance performed throughout the tools life (lubricating bearings, etc.), to even the age of the tool (as the brushes on brushed electric motors eventually wear out).

The following steps will help in disassembling the Hackzall and removing the electric motor from the tool's PC board. The use of a soldering iron is required to remove wiring around the trigger so soldering skills and knowledge are needed. Be sure to remove any source of power to the tool prior to beginning this repair.

Tools

-

-

Remove the screws holding the shell of the device together. Each screw size varies; you will use a T9 Torx screwdriver for one size 7.0 mm.

-

Use a T10 Torx screwdriver to remove one 14.0 mm screw.

-

Use a T15 Torx screwdriver for the remaining eight screws that are 16.0 mm.

-

Remove the casing to reveal all of the internal components.

-

-

-

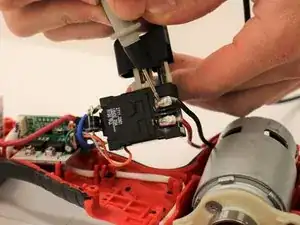

Find the red and black wire running from the back of the motor to the trigger mechanism.

-

With a soldering iron remove the two solders on the trigger mechanism.

-

-

-

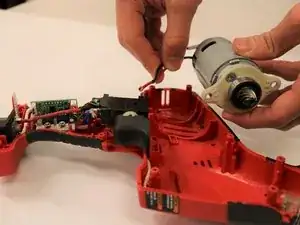

Remove the two screws connecting the motor to the gear box with a T15 torx screwdriver.

-

The motor is now free and can be removed from the tool.

-

To reassemble your device, follow these instructions in reverse order.

2 comments

Is there any chance to change only brushes in this motor?

That’s my exact question as well, nobody seems to cover this..