Introduction

A desoldering pump (or solder sucker) is a handy tool that sucks molten solder. You can use it to desolder through-hole components on a circuit board or to rework bad solder joints.

This guide shows how to use and clean iFixit’s desoldering pump. You may need to use some soldering wick to clean up any solder remnants—follow this guide on how to use soldering wick.

Tools

-

-

Firmly grasp the desoldering pump with your hand.

-

Depress the plunger until it locks in place.

-

-

-

Prime the desoldering pump by depressing the plunger.

-

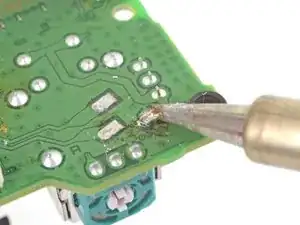

Heat the solder joint until the solder is liquified. To help with heat transfer, add some solder onto the soldering iron's tip.

-

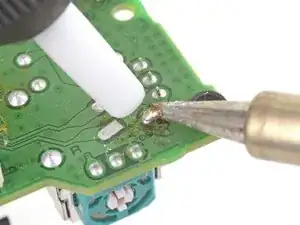

Position the pump's nozzle as close to the molten solder as possible.

-

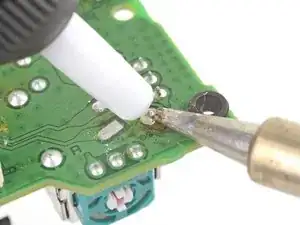

Press the side button to activate the pump.

-

Repeat the process until the joint is clean. You can also use solder wick to help soak up any remnant solder.

-

-

-

To clean the pump, prime and activate the pump a few times. This pushes a rod through the nozzle and ensures that solder doesn't block it.

-

Grasp the nozzle by its knurled edge.

-

Twist the nozzle counter-clockwise to unscrew it. This may be difficult due to a tight-fitting O-ring.

-

Remove the nozzle and clean out the pump interior.

-

For soldering instructions and tips, follow this guide.

One comment

Good review, but I’ve found that these small solder suckers don’t do a very good job. The much larger “Soldapult” (https://www.edsyn.com/product/DS017.html) provides much more suction and can often completely clear a joint in one use.

shamino -