Background and Identification

There are two types of impact drivers: manual drivers and electric drivers. Manual drivers deliver a powerful rotational force when hit on the back with a hammer. This becomes useful when more torque is needed to loosen a fastener than what can be achieved with a screwdriver. On the other hand, electric impact drivers provide a more consistent rotational force. They are used to drive screws forward.

Electric impact drivers are often perceived as being a mix of drills and impact wrenches. Electric impact drivers produce more torque than a drill but less torque than an impact wrench. Thus, impact drivers are commonly used when working with fasteners that are difficult to remove or drive forward. This is commonly the case when dealing with long screws and old, rusted lug nuts.

Additionally, the material of the base (what the fasteners are driven into) can affect how much torque is necessary. Another benefit to impact drivers is that they can drill through many materials by swapping out their blade. These materials include wood, steel, ceramic, plastic, etc.

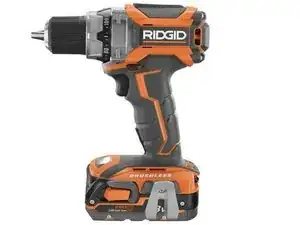

Impact drivers look similar to electric drills. They have a base, grippable handle, and rotating tip that can house a variety of attachments depending on the desired outcome of the job on hand.