Introduction

Use this guide to replace the idler pulley on your Whirlpool Duet WED87HED dryer.

This pulley provides tension to the drive belt. If it fails, the dryer will not spin properly, and the drive belt will likely break.

Usually, this part makes squeaking and grinding noises when it's failing. The motor may also overheat because the belt is hard to move.

Although the photos in this guide show the blower housing removed from the machine, this is mainly for clarity. You don't need to remove the blower housing to perform this repair.

Tools

Parts

-

-

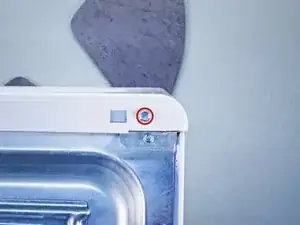

Use a 5/16 inch nut driver to remove the two 15.7 mm-long screws securing the top panel to the rear panel bracket.

-

-

-

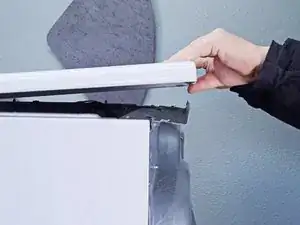

Lift the top panel upward to separate it from the chassis.

-

Remove the top panel from the machine.

-

-

-

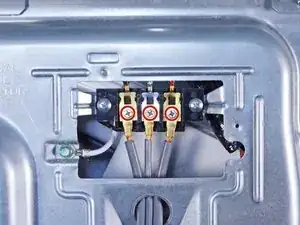

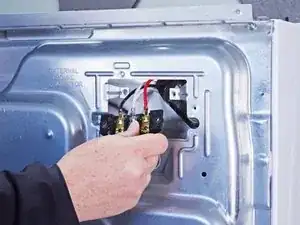

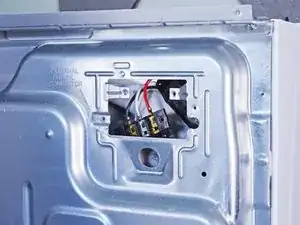

Use a 5/16 inch hex driver to remove the 16.5 mm-long green ground screw.

-

Use a Phillips driver to remove the two 15.3 mm‑long cord terminal block screws.

-

-

-

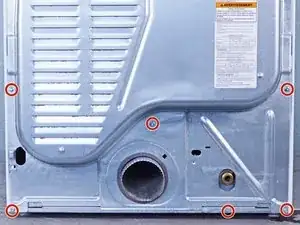

Use a 1/4 inch nut driver to remove the eleven rear panel screws.

-

Ten 20 mm-long screws

-

One 12.9 mm-long screw under the water inlet.

-

-

-

Use a 1/4 inch nut driver to remove the 16.4 mm-length screw holding the main board bracket to the chassis.

-

Use a 1/4 inch nut driver to remove the two 20 mm-long screws from the top rear of the machine.

-

-

-

Lift the panel about 1/2 inch and tilt it to the rear to release it from the vent pipe.

-

Slide the panel off the vent pipe and remove it.

-

-

-

Make sure that the vent pipe is fitted into the collar on the panel.

-

Make sure the tabs at the bottom are aligned to the bottom rim of the chassis.

-

Position the panel so its screw holes match with the chassis.

-

-

-

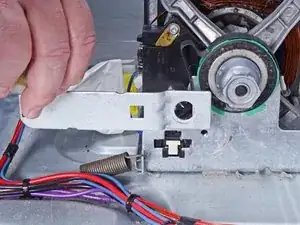

Use a 3/8 inch socket, or a nut driver, to remove the bolt securing the idler arm to the motor frame.

-

-

-

Move the idler arm toward the side of the dryer to unhook the idler arm tension spring from the arm.

-

Remove the idler arm.

-

-

-

Use long nose pliers to remove the plastic retaining clip from the groove in the idler pulley shaft.

-

To reassemble your device, follow these instructions in reverse order.

Repair didn’t go as planned? Ask our Answers community for help.