Introduction

Use this guide to replace the drum roller assembly (drum rollers and roller shafts) on your Whirlpool dryer.

The drum rollers serve as the bearings for the drum so that it tumbles freely. When they wear out or fail, they will make a rumbling or squeaking noise. The noise will be fairly loud, as the drum roller shafts are strongly mounted to the chassis of the dryer.

The drum rollers are best replaced as a set. If one has worn out, there's a good chance that the others will follow since they all have bearings in them.

Check the drum roller shafts for wear when you are replacing each roller. If you see wear marks but cannot feel a groove with your fingernail or fingertip on the shaft, it's probably still serviceable. The shafts only require replacement if they're damaged.

This guide will work for most Whirlpool dryers. This guide is written with a model WED87HED dryer. If you have a different model, you may encounter some minor disassembly differences, but the overall repair process will be the same.

Tools

-

-

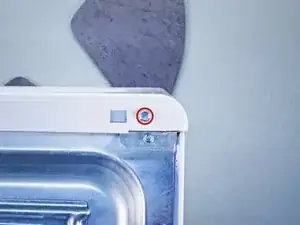

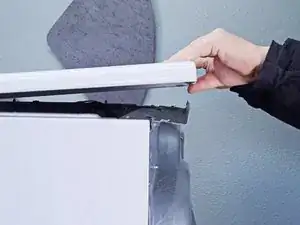

Lift the top panel upward to separate it from the chassis.

-

Remove the top panel from the machine.

-

-

-

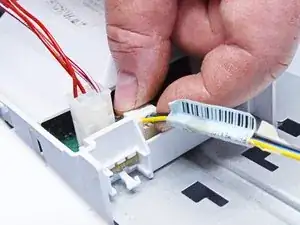

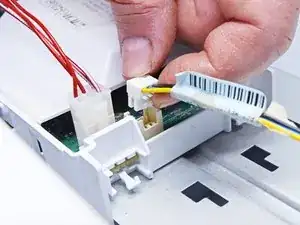

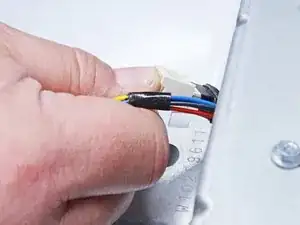

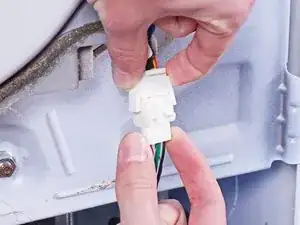

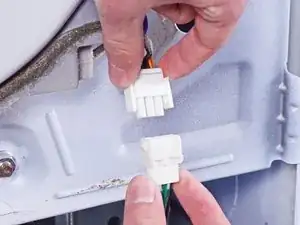

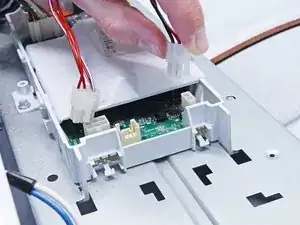

Use a small flat blade screwdriver or a spudger to unlatch both sides of the door switch connector.

-

Unplug the connector.

-

-

-

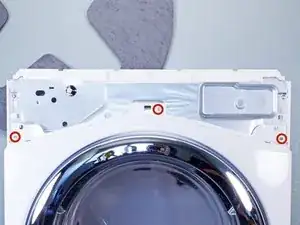

Remove the upper front panel sheet metal screws.

-

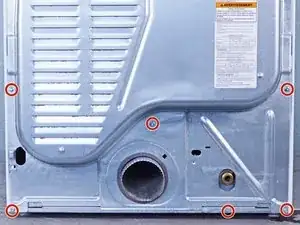

Tilt the machine backwards and prop it securely, or have a friend hold it.

-

Remove the sheet metal screws on the bottom edge of the panel.

-

-

-

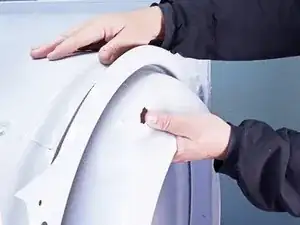

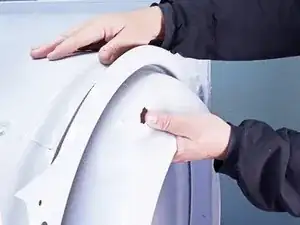

Pull the bottom of the panel away from the chassis about two to three inches.

-

Lift the front panel off the small tabs on the chassis near the top of the panel and remove it.

-

-

-

Remove the screw holding the main board bracket to the chassis.

-

Remove the screws from the top rear of the machine.

-

-

-

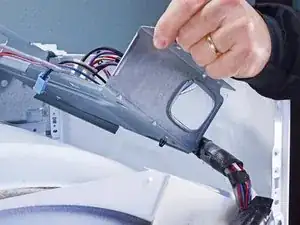

Lift the panel about 1/2 inch and tilt it to the rear to release it from the vent pipe.

-

Slide the panel off the vent pipe and remove it.

-

-

-

Make sure that the vent pipe is fitted into the collar on the panel.

-

Make sure the tabs at the bottom are aligned to the bottom rim of the chassis.

-

Position the panel so its screw holes match with the chassis.

-

-

-

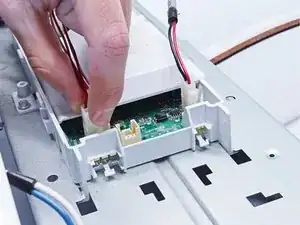

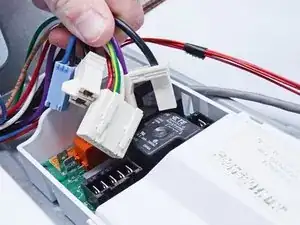

Lift the rear corner of the main board nearest to the side walls of the chassis.

-

Slide the main board toward the front of the dryer to release the tabs securing it to the main board bracket.

-

-

-

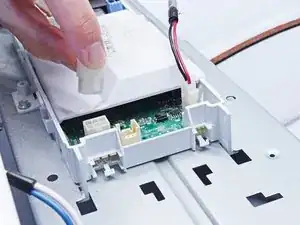

Lift off the main board bracket from the chassis and turn it so the bottom is exposed.

-

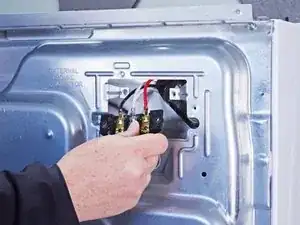

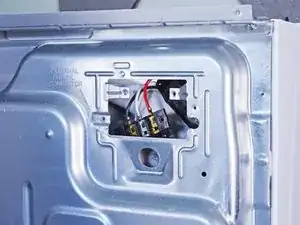

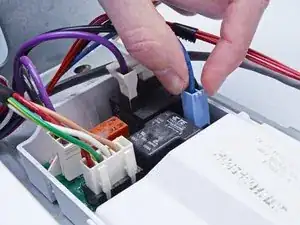

Using long nose or slip joint pliers, pinch the locking wings of the harness retainer clamp.

-

Separate the harness from the main board bracket and remove the main board bracket.

-

-

-

Remove the screws securing the upper front bulkhead to the front of the chassis.

-

Remove the sheet metal screws securing the top plastic portion to the upper front bulkhead.

-

-

-

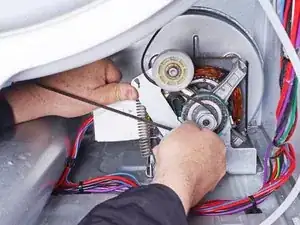

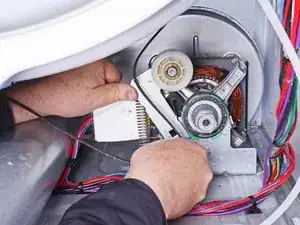

Push the idler arm (the metal upside-down "L") up to relieve the tension on the drive belt.

-

Remove the belt from the motor pulley.

-

Gently lower the idler arm until it rests parallel to the dryer floor.

-

-

-

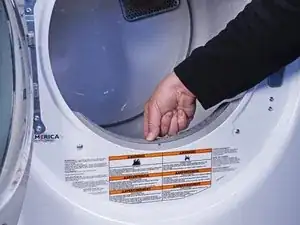

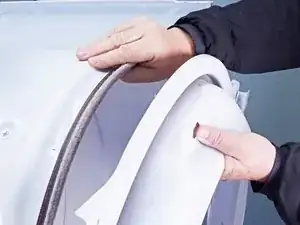

Lower the bulkhead about 2 inches to free the drum rollers tucked under the drum.

-

While supporting the drum, remove the lower front bulkhead.

-

-

-

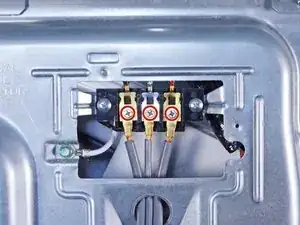

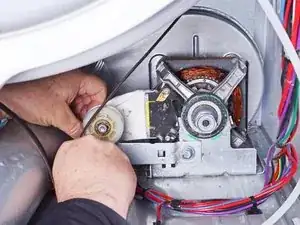

Slide the roller unit off the roller mounting shaft.

-

Repeat the last two steps for each drum support roller on the dryer.

-

-

-

Remove the drum roller shaft.

-

Repeat the last two steps for each damaged drum support roller shaft.

-

To reassemble your device, follow these instructions in reverse order.

Repair didn’t go as planned? Ask our Answers community for help.