Introduction

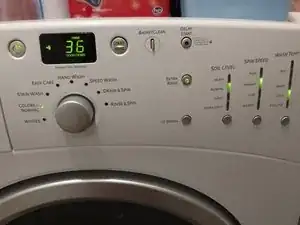

After ~10yrs the buttons weren't working right on our WBVH5300K0WW GE front load washing machine. Eventually pressing harder would trigger the display over buttons to the left of the button being pressed. I will explain how you can replace the tactile switches instead of the entire control board. Note: To do this you should be comfortable with soldering and de-soldering parts on a circuit board and have the proper equipment (soldering iron, solder sucker, ohm meter).

Tools

Parts

-

-

Read through the entire guide. and have a look at your control panel and switches in case they are different.

-

I found the right size switches at digikey.com part# 2449-CR1102H4.3F160CT-ND. Part# 2449-CR1102H4.3F260CT-ND is the same size but requires 260g of force to actuate the switch instead of 160g. Note: I can't seem to change the link for the second part # so if ordering the 260g force switch change 160 to 260 on the part #.

-

My washing machine had 9 switches so I ordered 10 (of both switches). I installed the 160g force switches as they took about the same force to actuate as the original switches.

-

My circuit boards have plenty of space around the switches. Any momentary tactile switch that is roughly 6.2mm on a side with the top of the button about 4.4mm above the board with only two pins with a pin spacing of 5-5.08mm should work.

-

-

-

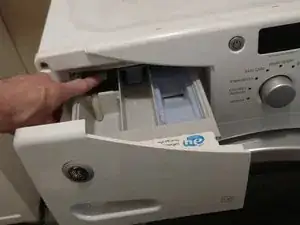

Slide out the soap drawer and gently push down on the tab while sliding it out.

-

Note: There will probably be water in the soap drawer so empty it and set it to the side.

-

-

-

Remove the screw on the bottom left side that sits behind the soap drawer.

-

Put the screw with the drawer as many of the screws are different sizes.

-

Note: I found it helpful to use blue painters tape and tape the screws in groups to the parts being removed or to the washing machine top near where they screw in.

-

-

-

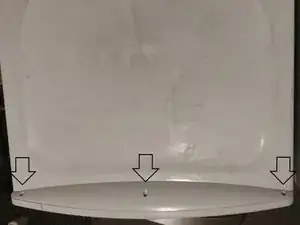

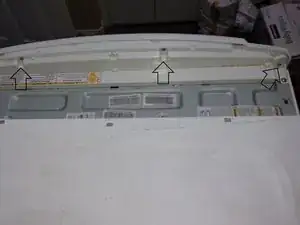

The picture is looking down on the washing machine from above. Remove the three screws holding the curved plastic piece on.

-

Gently pry the front top back and it should pop off.

-

Set it aside with the three screws (preferably taped to the plastic).

-

-

-

Unplug the washing machine.

-

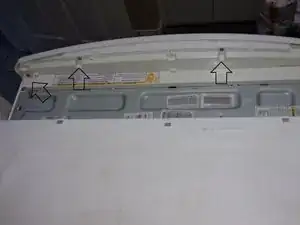

Remove the three screws at the back that hold the top on. Note: There are extra holes on either side of the outside screws. You may want to mark the hole that has the screw with a pencil or piece of tape.

-

Slide the top towards the rear about 1/2-1"

-

Raise the front edge of the top a few inches and slide the top back another 3-4". You should be able to find a position where the top lies flat on the washer.

-

-

-

Remove the four screws that secure the control panel.

-

With your hands on either side of the top lip of the control panel gently pull up and forward until the control panel moves forward.

-

Pull gently on the bottom right of the control panel to release the clips holding the control panel in place.

-

-

-

The two arrows on the right show the clips that were holding the right side in place.

-

At this point you could use a ohm meter to test some of the switches. The resistance when the switch is pressed should be a few ohms or less.

-

My switches measured between 200 ohms and 2K ohms when pressed and were likely the problem.

-

The picture with the circles show where a few of the switches are. Again, make sure the washing machine is unplugged. Put an ohm meter across the two large solder blobs in the circle and press the button. You may need someone to hold the control panel while you do this.

-

If this is too awkward you can remove the control panel and then test the switches (see the next step).

-

My meter showed about 7K ohms when not pressed. Note: The 7K ohms is from resistors on the board, not the switch. When the switch is pressed the resistance between the solder blobs should be a few ohms or less. If the resistance is much higher the switch is probably bad and should be replaced.

-

-

-

Assuming your switches tested bad it's time to remove the control panel.

-

I recommend taking a few pictures of the connecters before proceeding. I believe each of my connectors would only fit in one place but yours could be different.

-

Each connection has a tab that needs to be pressed when removing the connector.

-

The arrows point to the few tabs visible in this picture.

-

-

-

Note: I don't know how static sensitive the circuit boards are so if the humidity is quite low (meaning static can build up and you may zap something by touching it) try grounding yourself before you touch the circuit board. If you get up and walk around, ground yourself before touching the boards again.

-

If you have an appliance with a metal body and a three pronged electrical cord (a microwave etc) you can touch the metal case to ground yourself. Note: You DO NOT need to turn on the appliance, just have it plugged in.

-

The switches are on the two lower boards so remove the top board by removing the five screws (first picture) holding it in place.

-

The second picture shows where you should put your fingers to gently pull the plastic bar up over the standoffs (where the screws attach).

-

Once the plastic bar is free pull the board towards you a bit. Notice how the back of the board fits between plastic tabs at the back. This will be important when re-assembling the boards.

-

You can gently lay the top board over the back leaving all the ribbon cables attached (third picture).

-

-

-

Remove the four screws securing the right circuit board.

-

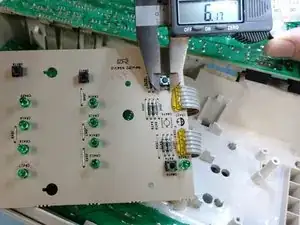

You can gently lift and flip the board to the left (as shown in the second picture). You can see the five switches on the front of the board.

-

It may be helpful to use a pen and draw a circle around each switch on the back (green side) of the board. This may save time when de-soldering the switches. Note: If any of your switches tested bad I'd change them all. At 20 cents each it's not worth opening the washing machine again later.

-

If you haven't measured the switches yet now is a good time. The third picture shows how I used a digital caliper to measure the switch so I knew what to order.

-

-

-

Note: When I was replacing the switches the smell from the board/solder was awful. I'd recommend doing this outside with a fan to gently blow the fumes away.

-

Again, I assume you know how to solder & de-solder the switches. I used a solder sucker to suck the solder of all the switch connections.

-

Note: I don't have a picture for de-soldering because at the time I wasn't thinking about writing this guide.

-

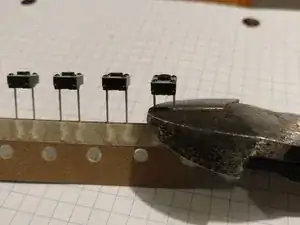

Try removing and replacing just one switch at first. This way you can compare the physical size, height, pin spacing, and actuator force between the new and old switch.

-

Once as much of the solder as possible is removed from the pins on the first switch I used a small flathead screwdriver to push on the pins to break them free from the board. If that doesn't work use the screw driver to gently pry the switch out from the front while heating the solder from the bottom.

-

-

-

Once the old switch is removed cut off one of the new switches (first picture) and compare the two switches. Leave enough pin length. You can always cut it shorter after soldering. Make sure it fits in the hole and that the button is roughly the same height as the old switch.

-

Note: The holes in my board are much larger than needed, even for the old switches. I found it helped to bend the pins to keep the switch from falling out of the board when I flip the board over to solder it.

-

Put the new switch in and hold it in place with one hand. Use your other hand to bend the leads in opposite directions. Bend it along the wide side of the rectangular leg (the easy way). The second picture shows the bent legs after one switch fell out before I could solder it.

-

Solder one of the switch legs to the board. Then flip the board over and see if the switch is lined up with the switch outline drawn on the front of the board. If it doesn't look centered, heat the solder and slide the switch a bit until centered.

-

Once the switch is centered put the board in place and hold it down while pressing the button on the front panel for the switch you just replaced. If you hear the switch click when the button is pressed then the switch is in the right place. If it clicked solder the remaining pin to the board.

-

If it doesn't click you probably need to move the switch a bit to line up with the plunger for that switch (arrows in third picture). Try looking at the plunger and the switch as you put the board in place to get an idea which way to move the switch. Re-heat the solder and slide the switch as needed and solder the remaining pin.

-

-

-

Once all the switches on the board have been replaced cut off excess lead length from the new switches.

-

Reinstall the board and screw it down.

-

Press each button one more time and listen for the click.

-

-

-

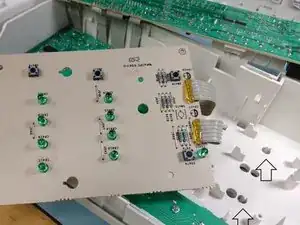

Unscrew the left circuit board. Note: Mine had spots for 7 screws but only six were installed. Might not mater but I took a picture and made sure to put the screws back in the same holes.

-

The second picture shows two plastic tabs that have to be pressed towards each other to release the board. The tabs are far enough apart that I could press one at a time while lifting that side of the board.

-

Once the left board is loose change all the switches and check the alignment (listen for the click, same as the last board).

-

Trim the excess lead length.

-

Once all switches work screw the board back down and listen for clicks one last time.

-

-

-

The three arrows show where the rear edge of the board has to go to be held in place. The board should be between the two vertical ridges and the triangular tab on the top.

-

Slide the board with the plastic bar over the standoffs.

-

Screw the board down.

-

-

-

Reinstall all the wiring to the control panel and compare it to your picture to make sure it's right.

-

Go in reverse order to put the rest of the washing machine back together.

-

Note: When I was done I plugged in the washing machine and all the buttons worked (and there was much rejoicing).

-

The next day my wife tried to do a load of wash. She said it wasn't filling with water and sounded different so she unplugged it.

-

Hours later, when I got home, I plugged it back in. It knew it lost power without finishing the cycle so it tried to drain the water (no water to drain) and then unlocked the door.

-

I did a load of wash and it worked fine. Not sure if there was a problem or she was confused and unplugged it when it was working. Don't see how changing switches would cause it to act funny.

-

Either way it works fine now. We've done dozens of loads with out a problems.

-

Good luck.

-

To reassemble your device, follow these instructions in reverse order.

One comment

My conservatortop load washer will not turn on