Introduction

If the drain valve is not opened properly, the most likely error pattern is as follows: after rinsing, the pressure is not taken from the brew group, the brew group motor continues to try to work, sounds very agonized. This process repeats itself a few times. The drainage motor from model Z6 can be removed quite easily. Often it can be restarted and it is not necessary to replace it.

Note: some pictures are from a different model and may differ slightly.

Tools

-

-

Turn the machine so the back is facing toward the front.

-

The Jura sign must be removed. Turn it a few millimeters counterclickwise.

-

Remove the Jura sign.

-

-

-

Behind the Jura sign are two screws with an oval head. They have to be removed.

-

These screws have an oval head that makes them look like rivets (picture 2). You need to use a special bit for their removal. If the right bit is not available, it could be done with a pair of needle nose pliers. Jura wants to keep us out of our own machines!!!!

-

-

-

Remove the Torx T15 screw on the front wall of the side panel.

-

In the side part there is a lid over the brew group. The lid is fastened at the top with two oval head screws. Remove those to remove the lid.

-

With the cover removed the brew group becomes visible

-

-

-

This step shows how to remove the top cover

-

Remove the powder tray and all coffee beans.

-

The cover is fastened with three Torx T15 screws. Those are easily visible under the covers as well as the small cover on the left back side.

-

Remove the two Phillips screws on the bean container and remove the bean container.

-

Lift the cover upwards.

-

-

-

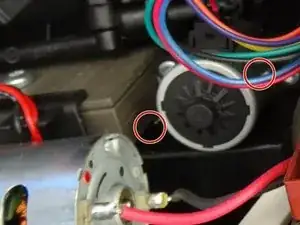

The drainage motor on the Z6 and following models is fixed with two Torx T15 screws. Unscrew them and pull out the motor.

-

Leave the cables connected to the motor for the time being. Trigger a flushing process and observe whether the pin moves back and forth. If not, the gearbox is blocked. You may be able to get it going with the following steps.

-

-

-

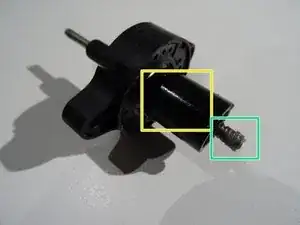

The gearbox (the black plastic part) is attached to the metal engine block with four metal tabs. Straighten the tabs with a small screwdriver.

-

Pull the gearbox off the engine block.

-

-

-

Turn the armature of the motor while holding the pin. Check whether the pin moves back and forth.

-

This probably solves the blockage. Grease the worm (and the pin) again a little. Position the worm so that it protrudes about 3 mm.

-

Reassemble the motor and bend the retaining tabs on the metal housing until it is tight.

-

To reassemble your device, follow these instructions in reverse order.

3 comments

The issue is likely a seized bearing. So when at step 11. Pull off the black cylinder and spray a penetrating lubricant (silicone spray) onto the bearing you can now see. The middle section should spin freely with no resistance.

D Wish -

Having serviced a E8 brewgroup and still no coffee I bought a new brewgroup and still no coffee but at least I can sell my old serviced group - this little hack on motor has proved this was the culprit. - it working again but coffee is weak but at least I have a clue to fix properly and not spend the £300 Jura and or other “experts” wanted to look at it plus the parts

Congratulations! If the coffee becomes weak, you should check the grinder. How many cups does the counter show? After more than 10000 cups, it may be worn out.

VauWeh -