Introduction

Tools

Parts

-

-

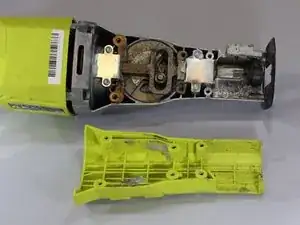

After following prerequisite guides to get to the presented step, remove motor assembly from back housing.

-

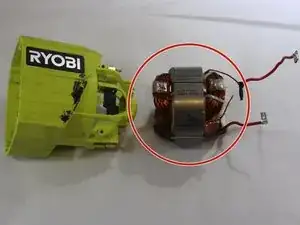

Motor Assembly

-

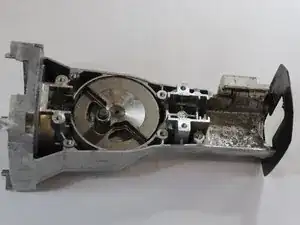

Motor Assembly Housing

-

-

-

Using pliers to grab onto the elongated aluminium exterior of the housing, begin to slowly wiggle the motor assembly housing until it comes loose.

-

-

-

After the wires have been detached it should be relatively easy to remove and replace the Motor Assembly Housing

-

Motor Assembly Housing

-

Conclusion

To reassemble your device, follow these instructions in reverse order.