Introduction

Bad capacitors can be identified by looking at them. This guide will walk through the steps of opening the monitor, locating bad capacitors, selecting replacements, and the soldering required.

Tools

-

-

These steps are as generic as possible, since most LCD displays use a similar design. However, you will need to think carefully about how to take the display apart so you can put it back together, and have it still work!

-

The images are from Repair ViewSonic VX924 LCD Monitor Blinking Green power Button (youtube). You should watch it through once to get an idea for what it's like.

-

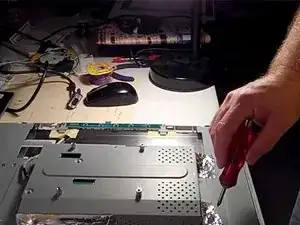

First, remove the plastic back of the monitor. The stand/pedestal may be attached by screws, or the back and the stand may all be one unit.

-

Keep the screws you removed with the plastic back. That way they won't get mixed up with the screws you take out of the internal parts.

-

There is also probably some sort of snap-on device molded into the plastic back.

-

In the video, a piece of steel is used. A screwdriver or a piece of strong, flat plastic can also do the job.

-

Snapping the back off should take some strength; however, too much force will permanently damage the plastic.

-

Start with very little force and poke the edges of the back. If one corner moves easily but another corner seems solid, then you may have missed a screw. Gradually increase the force you are using until the snaps come off.

-

-

-

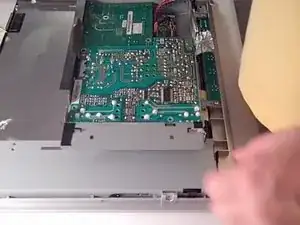

After removing the back, you need to unscrew the power unit.

-

Some displays use an external "brick" and have a 12V DC power plug.

-

Most displays, especially larger ones, have an AC plug (wall outlet). This guide shows a display with an AC plug.

-

Locate the power unit and remove any screws to access it.

-

You may also need to remove protecting tape. This tape blocks RF noise ("static") from distorting the display. It is ok to cut the tape carefully, or you may be able to unpeel it.

-

Unplug all the cables that come from the power unit and supply power to the other parts of the display.

-

Be sure you memorize how they go back together!

-

It's usually a good idea to pull out your digital camera and shoot pictures of the boards before you take them apart. This will help you put them together the same way.

-

-

-

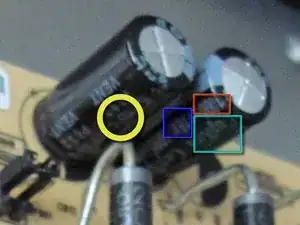

Identifying bad capacitors is fairly simple. Start with a search for images of bad capacitors to see what they look like.

-

If one capacitor has failed, there is a good chance the ones around it will fail, or may have partially failed. They were manufactured around the same time. Also, when a component fails, the rest of the circuit can be damaged by the electrical stress.

-

Doing them all at the same time is fairly easy.

-

New capacitors cost a few cents.

-

Each capacitor is coded on the side with:

-

Manufacturer and/or Product (Green box in the image)

-

Red box: Capacity (micro Farads); Blue box: Voltage (V); Yellow circle: Temperature Rating (C)

-

Notice also how the capacitor on the right has obviously "blown out".

-

-

-

You can get replacement capacitors from Mouser, Digi-key, or Arrow, or a local electronics parts store.

-

Capacity (micro Farads)

-

Voltage (V)

-

Temperature Rating (C)

-

Capacitor Diameter (mm)

-

Obviously, the manufacturer is not something you need to match.

-

You can go over on capacitor ratings to some extent so the monitor has more of a safety level when in use and less likey to blow to voltage. *this can be bad if the capacitor is failing due to over voltage, sometimes the cap is like a surge protector because it fails open.

-

-

-

Use a screwdriver or piece of metal to short across the legs of the old capacitors, while they are still in the board. This will "short out" any remaining power left in them so they don't spark or shock you while you do the repair.

-

Using a soldering iron, remove the old capacitors. Then solder in the new ones.

-

Replace the board and screw it into place.

-

Replace all the cables that you removed.

-

If you feel brave, you may want to test the display before putting the plastic back on.

-

To reassemble your device, follow these instructions in reverse order.

5 comments

Samsung : sold not easylly melting. What to do?

A year later, but buy flux. Will help things. Also let the soldering iron (and solder) heat up properly and be patient

Completely agree with Bruno. Flux and nice hot soldering iron.

Else cut the capacitor leads and solder the new ones to the old leads - avoids possible damage to the printed circuit boards