Introduction

The flute I'm about to show how to repair is a French Model flute (open hole keys). However, this method is applicable to the Plateau Model as well as other types of traditional concert flutes. If the connected keys on your flute aren't synchronized properly, follow step 1 and then skip ahead to step 40. If your flute has sticky keys, after following the first step, skip ahead to step 41. If your key has a missing pad, complete the first step and skip ahead to step 42. If your flute still won't play after completing these steps, then continue from step 2. Based on the location of the key needing repaired, some steps may not be necessary. Follow the instructions contained in the guide for details.

Tools

Parts

-

-

Instead, grasp it by the tenon section, where you won't put stress on the springs.

-

Remove the head piece in a similar fashion.

-

-

-

On the other side of the flute, remove the screw connected to the same rail from the previous step.

-

That rail should be free when you loosen the screw.

-

-

-

Push the rail out of the small groove.

-

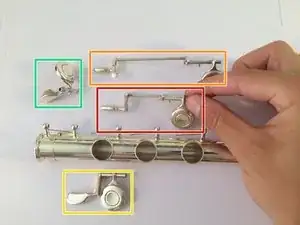

Weave the two trill keys (D and D#) out from underneath the springs.

-

-

-

Next, loosen the screw connected to the C, B flat, and A keys. This screw is actually a rod. Pull this rod out using your fingers.

-

-

-

Remove the C key. This will make the next steps easier to complete .

-

On the same rail, remove the rest of the keys (B flat and G).

-

There should be a point where it connects. Just pop it out and remove the rail.

-

-

-

The next step is to loosen the screw that holds the inline G keys.

-

Same drill: pull out the rod that holds it together.

-

-

-

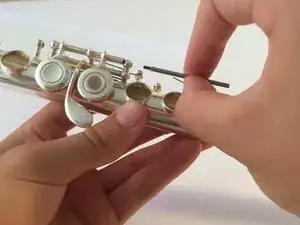

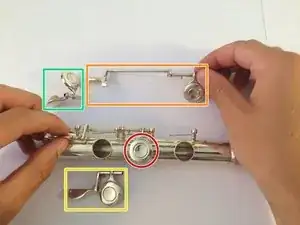

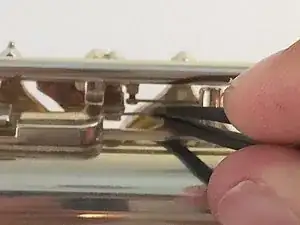

To make the removal of the inline G keys easier, use tweezers to move the spring out of position.

-

The spring will hang loose for now.

-

-

-

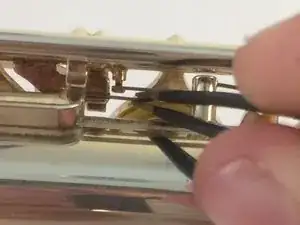

This is the most difficult rod to remove, so to make it a little easier on yourself, get the spring out of the way by moving it up into the groove.

-

Don't worry about bending the spring too much. If it loses it's original tension, it can be easily be corrected by stretching it in the opposite direction.

-

-

-

Disassembling the foot joint is simple. Loosen the screw at the end of the rail and pull out the long rod holding it all together.

-

-

-

When you pull out the rod, everything will fall apart. This is okay, it is what is supposed to happen. Just be sure not to lose any parts in the process!

-

-

-

Using the screwdriver, gently lift the pad out of the cup.

-

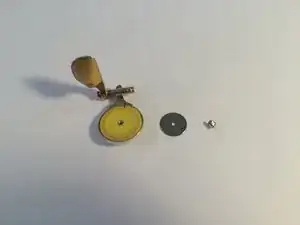

Behind the pad there will most likely be a couple paper shims that were placed there previously.

-

The items laid out left to right go in the cup from bottom to top, respectively.

-

-

-

The amount of additional paper shims you may need ultimately depends on the condition of the repair.

-

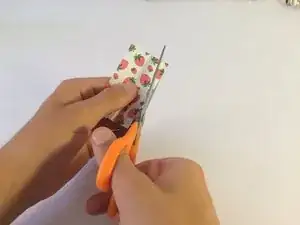

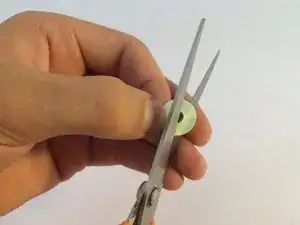

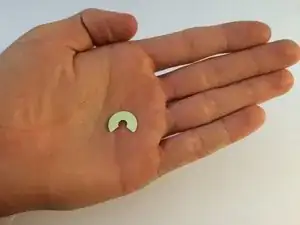

Using scissors, cut out about a third of a new paper shim.

-

-

-

Place the cut paper shim back into the cup after the supporting, whole shims. You may need to place more than one cut paper shim if the misalignment is more severe.

-

-

-

For the reassembly of the foot joint, the keys go back in this order:

-

C roller.

-

B roller.

-

This part has a "gizmo," which is a distinct tab attached to the roller.

-

C# touch.

-

D# touch (pinky key).

-

-

-

It's a bit tricky trying to keep all the pieces lined up when inserting the rod.

-

It's a bit easier to slide it in one section at a time, rather than trying to do them all in one shot.

-

-

-

You'll notice that all the keys aren't open. This is because the springs aren't in the proper place.

-

To fix this, use the ridged tweezers to grab the spring and put it behind the peg.

-

-

-

When putting the G# lever back in place, make sure its spring is loaded against the post on the right.

-

Follow the disassembly directions in reverse order, as well as these steps to ensure that all the springs are put back in place. The flute doesn't need to be taken apart a second time.

-

-

-

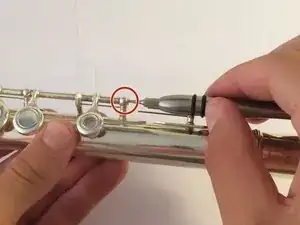

This is the spring by the C key.

-

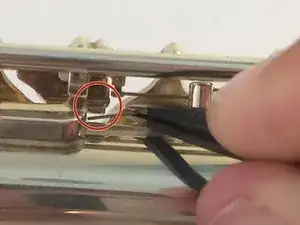

Notice that the spring is in front of the metal groove.

-

Use the tweezers to put the spring behind it and in the groove.

-

-

-

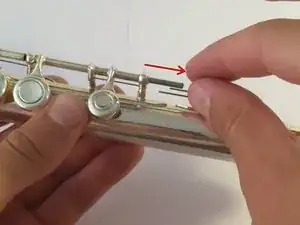

This is the spring of the B flat key (next to the C key).

-

Again, this spring needs to go behind the small plate, into a little slot.

-

-

-

This spring needs to be put back behind its peg.

-

For reference, that plate with the spring in its groove is the spring that was fixed in the previous step.

-

-

-

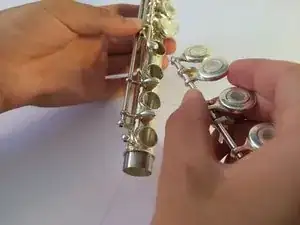

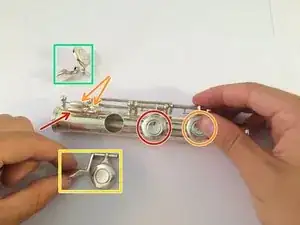

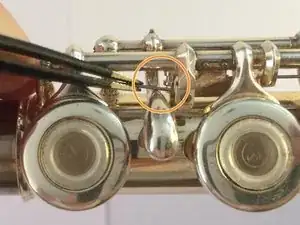

Align the two separate tabs so that the rod fits back through.

-

Make sure that the tip at the end of the skinny tab returns under its corresponding strip of metal.

-

-

-

In order for the reassembly to work for this piece, remember to put the trill keys under the corresponding springs.

-

Make sure the rail is rejoined at that point.

-

That tab fits behind the one fixed there.

-

-

-

This spring between the F and E keys isn't hard to reach. Fit it in the small groove.

-

The spring between the E and D keys goes behind a small peg.

-

-

-

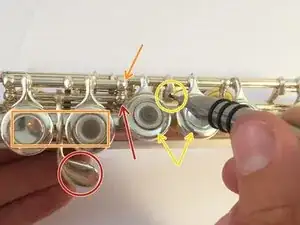

When putting your flute back together, some keys may seem either too easy or to hard to press. This is related to the tightness of the screws in the rails, as well as small screws between finger keys that have not yet been mentioned.

-

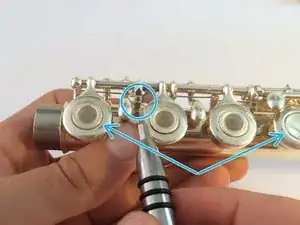

To adjust the G# lever, change the tightness in the corresponding screw in the railing.

-

To adjust the inline G keys, play with the screw in the attached rail on top of the G# lever railing.

-

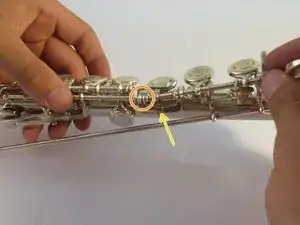

This screw, as well as the next two screws in this step, do not hold anything together. They act as modifiers that adjust the synchronization of connected keys not attached to a rod backbone.

-

This alters the F and F# pair.

-

This screw changes the coordination of the D and F# keys.

-

-

-

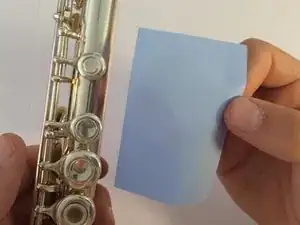

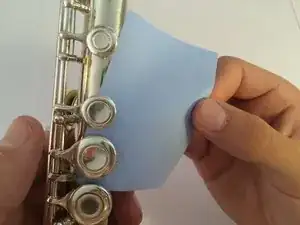

When practicing the flute for a good amount of time, finger keys often get sticky. This can affect the time it takes for the pressed key to return to its original open position, something fast playing musicians can't afford.

-

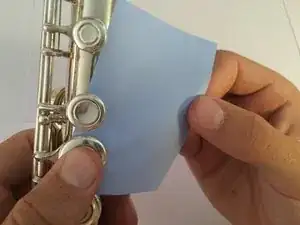

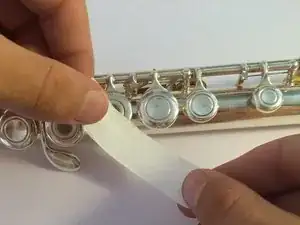

Put an oil absorbing sheet under the sticky key and lightly press down on the sheet.

-

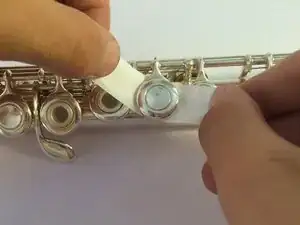

Release and gently remove the sheet.

-

-

-

In the case that you are missing a felt pad entirely (just a bare cup), you can still fix your flute temporarily.

-

Cut a small strip of teflon tape (about 4" )

-

Holding both ends, slip the tape under the key with the missing felt pad. It's quite the surgery, but manageable.

-

With the remaining tape, twist it together at the top to hold it in place.

-

This is a temporary fix, but works perfectly.

-