Introduction

-

-

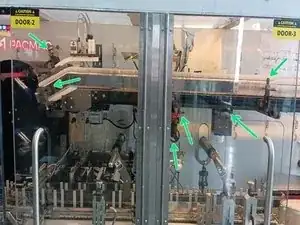

Carton Drive: The carton drive is the main drive of the machine where the carton picked by rotary pickup system is placed for further operations such as product insertion, tucking and coding.

-

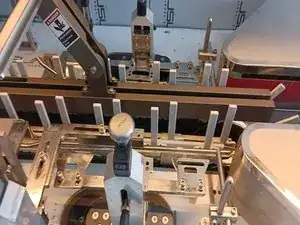

Width of carton drive is required to be adjusted as per size of respective carton.

-

To adjust the width of carton drive we need to rotate adjusting screw shown by arrow in fig.

-

for increasing width rotate it clockwise and vice versa.

-

-

-

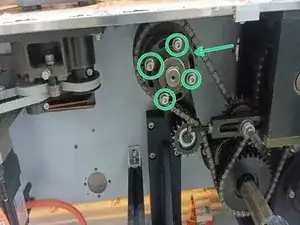

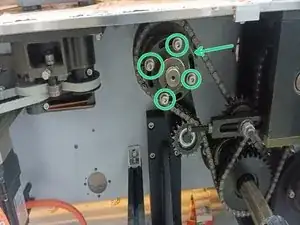

Product Drive: Product Infeed occurs on a dual timing belt-based pulley drive. On top of this belt drive, chain mounting adapters are provided, where product partition plastic pockets are press fit as shown in the diagram below. It moves products in pocket from feeding station to the loading station.

-

Based on the product width the pockets must be adjusted with the help of the following steps:

-

Loosen the bolts provided on front and back side near discharge area as shown in green circles above & Increase the gap by rotating the pulley in direction as shown by the arrow and Vice versa.

-

Place the product in pocket to verify the gap and ensure that there are few 1-2mm moving spaces.

-

-

-

Leaflet Magzine

-

The leaflet magazine holds stacks of folded leaflet. The guide keeps the leaflets from falling out of the magazine by adjustable side and top guide. When the leaflet level sensor is no longer blocked, a low-leaflet supply message will appear on the HMI and the warning light will illuminate to alert the operator to stack cartons on the magazine

-

Based on the leaflet width and height of the Leaflet magazine must be adjusted with the help of the following steps:

-

Remove all leaflet from the magazine.

-

Loosen the fasteners at the sides of leaflet magazine & slide magazine guide left-right for adjustment as per leaflet size.

-

-

-

Individual cartons are picked from the carton magazine by a rotary carton pickup unit and place them directly in front of a set of carton chain attachments. Vacuum cups attached to arm of each assembly is connected to the vacuum system by a vacuum dish assembly.

-

The carton pickup will feed a carton to match each pocket of product is detected entering the machine by the product sense sensor. As product is detected entering the machine, vacuum supply to the vacuum dish assembly will turn on & vacuum will then be supplied to the corresponding vacuum arm assembly through the built-in channels.

-

Loose the Allenkey bolt provided at back side of carton pich up also shown in fig.

-

Rotate height adjustment wheel clockwise (CW) to increase the height & vice versa to decrease height as per the carton. and tighten the Allen key bolt.

-

-

-

Remove all cartons from the magazine.

-

To adjust the height of carton magzine rotate the wheel shown in image clockwise (CW) to increase the height of magazine & vice versa to decrease height as per carton height.

-

Loosen the fastners provided at the side and bottom of carton magazine & slide magazine left-right and fornt back as per carton requirement.

-

-

-

Loose the fastners provided at the side of booklet guide and adjust the height as per booklet size.

-

To adjust the width of booklet as per booklet loose the bolts provided in slot at the bottom booklet support guide and adjust the width to accomodate booklet.

-

Change the booklet lander as per booklet requirement.

-

-

-

To accomodate cartons for different sizes we have to adjust the flap closing unit accordingly.

-

to adjust the flap closing unit we have to enter cam angle value in HMI for both front and back flap closing unit.

-

-

-

Need to change pusher head as per size of different product.

-

Also when we are shifting from one product to another of different sizes we need to do centering of pusher head. for that we need to loose the three bolts as shown in the fig and do the centering of the assembly and then lock the bolts in that posistion.

-

-

-

To accomodate cartons for different sizes we have to adjust the Tuck in assembly accordingly.

-

to adjust the flap closing unit we have to enter cam angle value in HMI to correct the position of tuck in assembly.

-

Also need to adjust tuck in guide and height of tuck in assembly as per different carton requirement.

-

To reassemble your device, follow these instructions in reverse order.