Introduction

Barrel clasps are on many pieces of jewelry, but there are only guides available on how to replace the clasp—not how to repair it. Taking a broken necklace to a jeweler or completely replacing the clasp can be expensive and time-consuming. To reduce waste and save broken jewelry, we will demonstrate how to fix a broken barrel clasp necklace while properly operating a soldering gun safely.

Tools

Parts

-

-

Locate the broken part of the ring that attaches through the back of the barrel clasp.

-

Bend the portion of the ring with needle nose pliers until the newly compact ring can be pushed through the barrel clasp and fit snug.

-

-

-

Plug in the electric soldering iron and set the solder temperature to the degrees that suits the melting point of both the soldering wire and the barrel clasp.

-

-

-

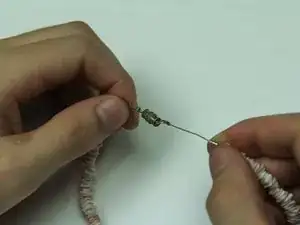

Solder the base of the barrel clasp where the metal ring fits in, intersecting the tips of the soldering gun and soldering wire.

-

-

-

Attach the barrel clasp necklace back together and hold each end of the necklace taught to test the solder strength.

-

To reassemble your device, follow these instructions in reverse order.