Introduction

Over time, the wire that runs up the back of the fan behind the blades may come into contact with the blades, and become damaged or severed. This guide is meant to show how to repair the damage.

Tools

-

-

Unscrew the 6 screws on the front of the fan.

-

Remove the face plate.

-

Flip the fan and repeat for the 6 screws on the back. They are in the same position as the front.

-

-

-

Unscrew the screws attaching the motor/blades to the frame.

-

Unscrew the screws attaching the plastic frame to the motor.

-

-

-

Plug in the soldering iron.

-

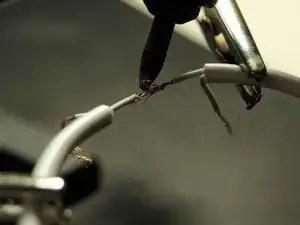

When the soldering iron is hot, solder the wires together.

-

Place the tip of the soldering iron on the wires directly.

-

Place the solder on the wire.

-

Remove the solder and soldering iron from the wire

-

Repeat this step with the second wire.

-

-

-

Use electrical tape to insulate the wires.

-

Wrap the tape around each wire.

-

Wrap tape around the outside of all of the wires.

-

To reassemble your device, follow these instructions in reverse order.

7 comments

Any tips for replacing the "Blue Plug" fuse after it's mysteriously blown in a Lasko box fan?

https://www.amazon.com/fused-safety-Lask...

I could hillbilly wire up a new plug to minimize the wire work, but don't want to start a fire either.

I would also like to know how to replace the plug end after the non-replaceable fuse inside the plug is blown.

Gung Ho -

I don't know bout you but I was able to “pop" my fan blades right off of motor. Now I'm just going to replace plug end and see if it'll work since fixing wires didn't help.

(Yep found fuse was blown. Why would they make the fuse non replaceable when they eventually blow? Wonder how many fans people have thrown out all because of a blown fuse??