Introduction

Here is a Kenmore 400 model 11029422801 with a clutch that was slipping. The washer went through all the programs but left the laundry soaking wet after the spin cycle. It sounded like it was spinning, but when we checked the drum while spinning, we noticed that it was not achieving full spinning speed. This was most evident on heavy loads.

Tools

Parts

-

-

Kenmore 400 washer that has difficulty spinning. It runs through the cycle but does not spin properly.

-

Open the lid

-

Remove cap from the agitator by using a flat tip screwdriver or similar.

-

-

-

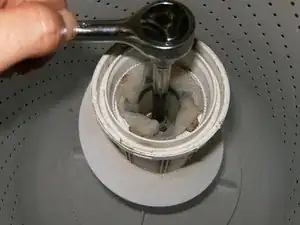

With the cap removed, a 7/16 hex bolt becomes visible.

-

Use a socket wrench with 4 inch extension to remove the bolt.

-

The agitator bolt measures 5/16 X 1 inches, 24 thread size

-

-

-

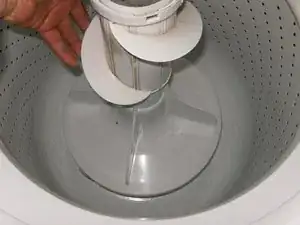

With the bolt removed, pull the agitator of the shaft.

-

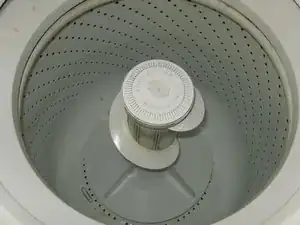

View of the drum with agitator removed

-

For ease of working on the bottom parts, lay the washer on its side.

-

-

-

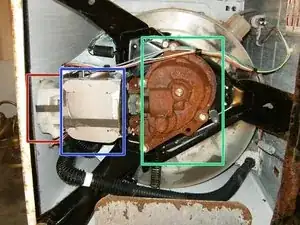

Main parts of the assembly include

-

Drain pump

-

Motor

-

Transmission

-

This is a direct drive model. No belts but a motor coupler connects the motor to transmission. Check for any cracks etc.

-

Remove the wiring harness from the motor

-

-

-

Remove the wiring harness from the clip on the transmission

-

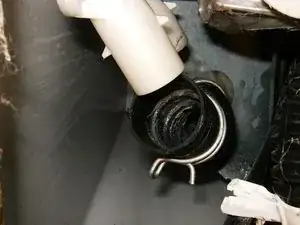

Drain lines from the drum and drain hose are connected to the pump with spring clamps.

-

Using a pair of pliers and squeezinge the opposite ends of the clamps together will loosen the clamp.

-

-

-

Pull the drain hose of the pump

-

Remove the tub-to-pump hose the same way

-

Remove the three 1/2inch bolts.

-

-

-

Here are the three bolts. They are 5/16 by 11/16 with a 1/2 inch hex head.

-

With the three bolts removed, pull the complete assembly out of the drum

-

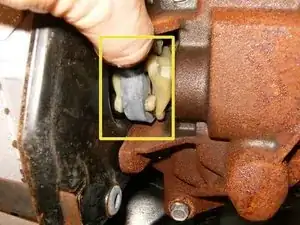

With the assembly removed, the clutch is now completely visible.

-

-

-

It is not necessary to replace the whole clutch. For this repair only the clutch band needs to be replaced

-

Using a pair of pliers to compress the spring will loosen the clutch band.

-

Lift the clutch band out of the clutch housing

-

Clutch band removed. Replace with model specific part.

-

To reassemble your device, follow these instructions in reverse order.

17 comments

Would this repair fix a 80 series Kenmore washer with same problem of no high-speed spinning

Possibly but it depends on what is going on with it. This one spun just sluggish and not „forcefull“ enough. It pretty much stopped spinning with a full load because of the weak clutch

How much do it cost to repair it

The complete repair kit was somewhere between USD $30-$40

I'm a jack of all if I can get it out I can rebuild it im a maintenance man at chicken proscenium plant we got to fixs all of it