Introduction

Use this guide to fix a clogged and oozing 3D printer hotend. Although other printers may use the same hotend, we will be looking at the Prusa i3 MK3S+.

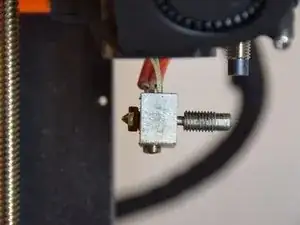

If your Prusa i3 MK3 is oozing burnt filament from the top of the heatblock, then you most likely have an incorrectly assembled hotend.

An incorrectly assembled hotend is a common problem that most people encounter when switching out their nozzles. The oozing might not be immediately apparent but can be visible either through the ooze dripping onto your prints or a build-up of filament on your heatblock.

In this guide, we will be heating the printer nozzle up to 285 Celsius, so please handle the parts with care. If you have removed a heated part and cannot yet re-insert it, then place it on something that can handle the heat, like a ceramic plate.

Tools

-

-

Set the nozzle temperature to your filament's recommended printing point.

-

While the printer is heating, gently tug the filament and pull it out.

-

-

-

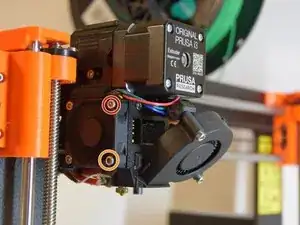

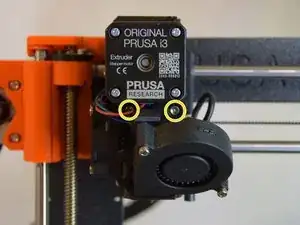

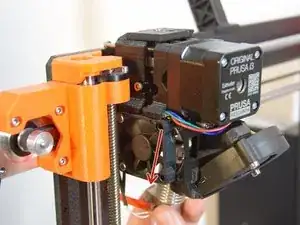

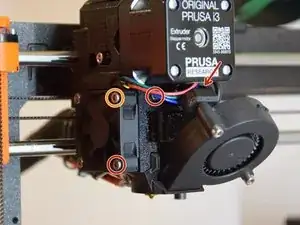

Remove the top right M3x14 heatsink fan screw.

-

Remove the bottom right M3x20 heatsink fan screw.

-

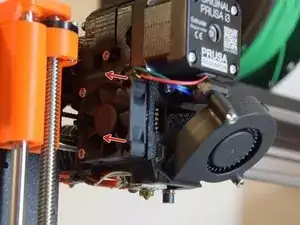

Loosen but do not remove the M3x14 screws located under the extruder motor.

-

Loosen but do not remove the M3x14 screws located at the top behind the extruder feeder.

-

-

-

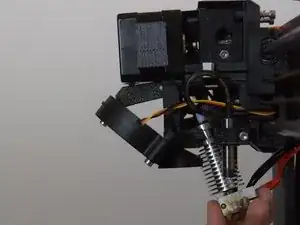

Ensure that the extruder motor cable has enough slack to be pulled apart.

-

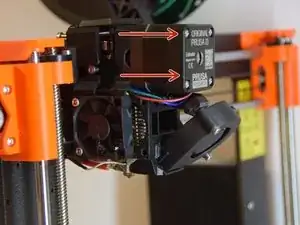

With the heatsink fan screws removed, gently pull apart the extruder encasing.

-

-

-

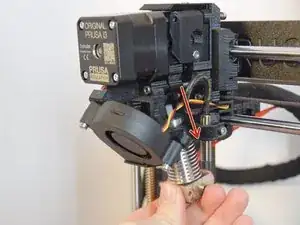

Heat up the nozzle to 285 degrees Celsius. The heat will cause the block to expand and allow you to safely remove the parts.

-

While gripping the block, unscrew the nozzle.

-

-

-

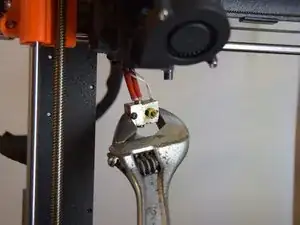

Grip the heatblock with the wrench.

-

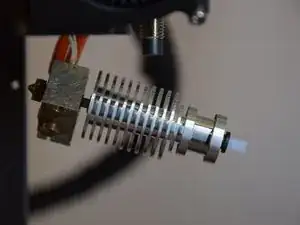

Gently unscrew the heatsink thread.

-

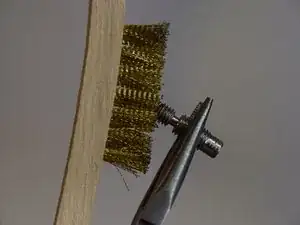

Clean the heatsink thread with the brush.

-

-

-

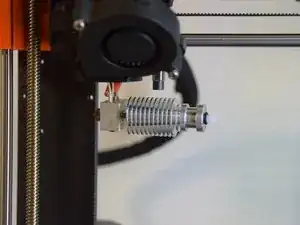

Heat the nozzle's temperature to 285 degrees Celsius for the heatblock to expand and grip it with a wrench.

-

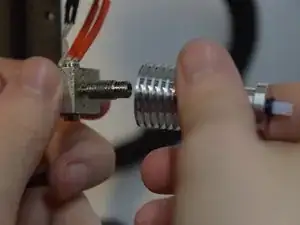

Gently reattach the heatsink thread with your pliers, leaving some slack so that it is not flush with the heatblock.

-

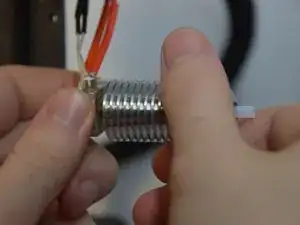

Re-screw the cleaned nozzle but leave a gap between the nozzle and heatblock.

-

Screw the heatsink thread until it is flush with the heatblock.

-

Tighten the nozzle once again until you feel the that the nozzle's thread is touching the heatsink thread to ensure that filament does not build up in the heatblock threads.

-

-

-

Re-screw the M3x14 screws.

-

Re-screw the M3x20 screw.

-

Your printer nozzle has now been properly cleaned and re-assembled!

-

Your extruder’s burning ooze problem has now been fixed, so you can now continue with your prints! Before you do, please remember to re-calibrate your printer.