Introduction

This guide demonstrates how to quickly and safely check, and, if necessary, replace the run capacitor in your residential HVAC condenser unit. This process can also be used, with some modification, to check other capacitors, such as the blower motor capacitor in the furnace of your HVAC system.

When following this guide please remember safety first: remember to turn the power off before you start and turn it back on only when you have everything reassembled.

Tools

-

-

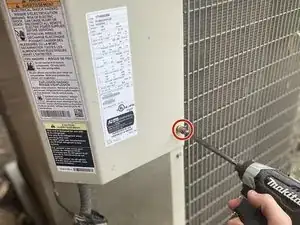

Use either a Phillips #2 screwdriver or a 1/4 inch Phillips bit to remove the two screws securing the electrical panel cover

-

Remove the electrical panel cover.

-

-

-

Use either a Phillips #2 screwdriver or a 1/4 inch Phillips bit to remove the two screws securing the capacitor bracket.

-

Lift the capacitor away from the electrical panel, with care not to damage or dislodge any wires.

-

-

-

Use the capacitor discharge tool to bridge the gap between the terminals labeled "Hum" (Compressor) and "common" (ground). This will discharge any stored electricity in the capacitance meter to prevent any damage to you and your capacitor meter.

-

Repeat the process with the "fan" terminal and the "common" terminal.

-

-

-

Use your capacitance meter to read the microfarads between the 3-prong terminal (Hum) and the 4-prong terminal (common).

-

Repeat the process between the 1-prong (fan) and the 4-prong terminal (common).

-

-

-

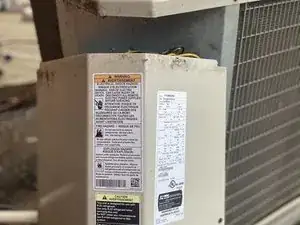

Compare the gathered readings with those printed on the capacitor label. If the numbers that you collected are roughly the same (within 0.4 microfarads) then the capacitor doesn't need to be replaced. If the difference is larger than 0.4 microfarads, then it's time to replace the capacitor.

-

To reassemble your device, follow these instructions in reverse order.