Introduction

The mini motor for the Glade Automatic Spray Holder is not functioning. Rather than throw the entire casing and motor away, this guide will help you replace the motor.

Tools

-

-

Press the button labelled glade to open the housing.

-

Locate the timer switch and slide it to off.

-

-

-

Pop one side of the hinge from its peg and slightly pull it away from the device.

-

Do the same with the opposite side of the device. Removing the cover will make it easier to work.

-

-

-

Remove the batteries to expose the terminals. The terminals are the thin metal pieces that hold the batteries in place.

-

Without the batteries, you can visually assess for problems like loose wires.

-

-

-

Use small needle nose pliers to gently remove each terminal. Check if any wires are disconnected or loose.

-

The terminals with negative connections (black wires) could have breaks or might have detached from the terminal base. Check for additional issues.

-

The bottom terminal is one piece instead of two pieces like the top ones.

-

-

-

Use the soldering gun and soldering electrical wire to solder the bared wire to the terminal.

-

-

-

The solder does not need to be beautiful, just functional.

-

Put the fixed terminal back into the correct place to hold the batteries.

-

-

-

Remove the four screws using Phillips screwdriver. Gently pull the screws straight out to avoid disrupting the components you are exposing.

-

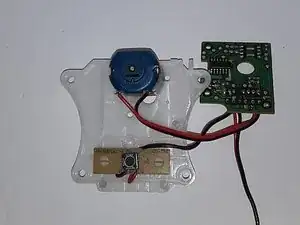

Once the cover is removed, take a picture to reference when you're reassembling the device. The larger electrical board is on the top. The plastic gears are easily moved out of their positions when removing cover and board.

-

-

-

The first circuit board to inspect has the timer switch on it. This circuit board is the larger of the two that are part of the device.

-

The circuit board is held in place by 3 pegs. The pegs are plastic. This means you do not need special tools to remove the circuit board. It will pop off using your fingers.

-

Flip the board over to look for loose wires or any burnt spots. This one is okay.

-

-

-

It is best to remove plastic gears before flipping the plastic plate holding everything together. The gears will fall out. Start with the fan shape gear. No tools are needed; each gear is held into place by pegs.

-

Next remove the largest gear. It is centrally located.

-

Lastly, remove the medium sized gear located towards the bottom left.

-

-

-

Next locate the small circuit board. Red arrows indicate where the wires are connected to the board.

-

Once pulled off the 2 pegs holding the small circuit board, the red wire came off of the board.

-

-

-

Solder the red wire back to the correct point on the circuit board. You'll be able to see the original factory solder point close to the edge of the board. It will be next to the black wire.

-

Once done with the solder, wait until it has cooled and pull gently to verify that it is securely attached to the circuit board.

-

Finished the circuit board and wire reattachment.

-

-

-

Locate the motor. It is metal with a blue top. A red wire and a black wire are attached to the blue top.

-

Flip the plastic plate holding the motor upside down.

-

Use a small Phillips head screwdriver to remove the screws. This will free the motor from the plate.

-

-

-

Cut the wires away from the old motor using the needle nose plier wire cutter, located next to the plier hinge.

-

Attach the red wire to the new motor with the soldering iron and solder. The red wire will go to the left side of the motor face with a metal strip on the blue part.

-

Repeat with the black wire to the right side of the motor.

-

To reassemble your device, follow these instructions in reverse order.