Introduction

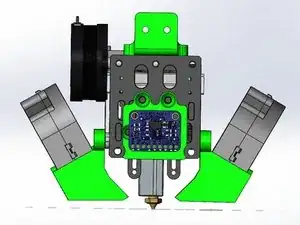

You will need a printed adapter to mount the ADXL345 to the rear of the X carriage. You can find one here

Parts

-

-

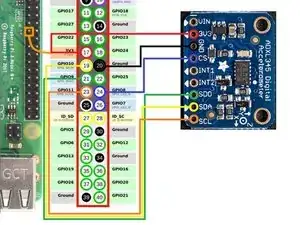

Connect the Accelerometer to the RPI

-

Accelerometer 3V3 to RPI pin 17 3.3v

-

Accelerometer GND to RPI pin 20 Ground

-

Accelerometer CS to RPI pin 24 GPIO08 (SPI0_CE0_N)

-

Accelerometer SDO 21 to RPI pin GPIO09 (SPI0_MISO)

-

Accelerometer SDA to RPI pin 19 GPIO10 (SPI0_MOSI)

-

Accelerometer SCL 23 to RPI pin GPIO11 (SPI0_SCLK)

-

-

-

You need to SSH into to your printer and install Numby.

-

~/klippy-env/bin/pip install -v numpy

-

sudo apt update

-

sudo apt install python3-numpy python3-matplotlib -y

-

Verify Linux SPI driver is enabled

-

sudo raspi-config

-

#3 Interface Options > P4 SPI > Yes > OK > Finish

-

-

-

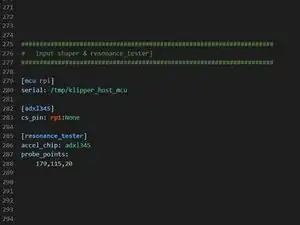

Uncomment the input shaper & resonance tester section in the config.

-

probe_points: It's recommended to use 1 point in the center of the bed slightly above. I used the same coordinates used when homing Z

-

Restart klipper with

-

RESTART

-

-

-

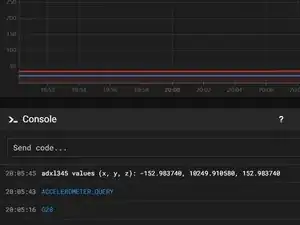

Check to make sure the RPI can communicate with the ADXL345 by running the following command in console

-

ACCELEROMETER_QUERY

-

It should return something like:

-

adxl345 values (x, y, z): -152.983740, 10249.910580, 152.983740

-

-

-

Home the printer.

-

During resonance testing the vibrations can become extremely violent. Make sure you're in proximity of the printer in case you need to cancel the test with M112

-

Now you can run the first resonance test for X

-

TEST_RESONANCES AXIS=X

-

When the test completes run it again for Y

-

TEST_RESONANCES AXIS=Y

-

When the test is complete it will generate CSV files stored on the pi.

-

-

-

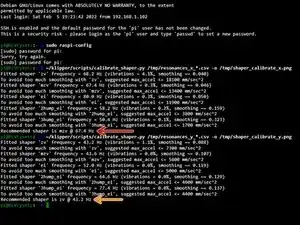

SSH back in to the printer and run the following 2 commands

-

~/klipper/scripts/calibrate_shaper.py /tmp/resonances_x_*.csv -o /tmp/shaper_calibrate_x.png

-

~/klipper/scripts/calibrate_shaper.py /tmp/resonances_y_*.csv -o /tmp/shaper_calibrate_y.png

-

This script will generate the charts /tmp/shaper_calibrate_x.png and /tmp/shaper_calibrate_y.png with frequency responses

-

You will also get the suggested frequencies for each input shaper, as well as which input shaper is recommended for your setup.

-

You can see my values for X

-

You can see my values for Y

-

-

-

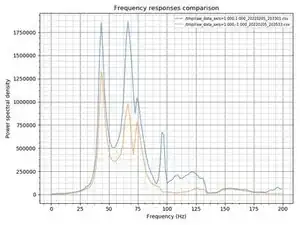

With a CoreXY you can also use Klipper to compare belt tension between X and Y. This doesn't tell you if the belts are too tight or too loose. It tells you have the belts are tensioned equally.

-

Run the following commands in the console

-

TEST_RESONANCES AXIS=1,1 OUTPUT=raw_data

-

TEST_RESONANCES AXIS=1,-1 OUTPUT=raw_data

-

SSH into the pi and run

-

~/klipper/scripts/graph_accelerometer.py -c /tmp/raw_data_axis*.csv -o /tmp/resonances.png

-

Based off the generated graph, X had much higher frequencies than Y. I had to tighten the left belt tensioner to to bring the frequencies closer to each other.

-

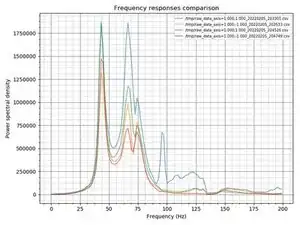

As you can see from the 2nd test the frequencies for X and Y are closer together, but could still use a little more adjustment. I think a lot of the frequency variation is due to my cable chain. At lower frequencies it rattles considerably more only when calibrating X.

-

2 comments

Great Post! You might want to add a paragraph on the RPi Microcontroller for multi mcu with the pi

gary -

You must have known delicious food, right? And now you will play a game called: